Company Profile

Introduction Baiyin Jinqi Chemical Technology CO., Ltd.was established in July, 2006. It locates in the National High-tech Industry Development Zone of Chinese Academy of Science of Baiyin City. The company is well-equippedwith fine equipment, qualified staff and high standard inspection methods. After years of development, its total assets mount to 26 million US dollars. The company is fully capable of producing annually 50 thousand tons of new-type oil field well cement lightening agent BYJ-1,[MORE]

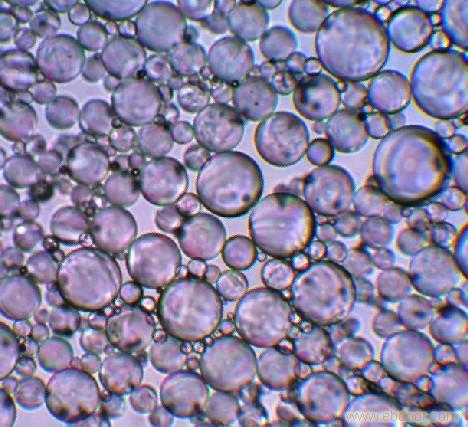

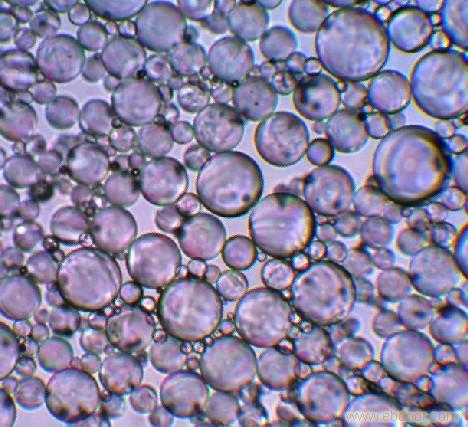

High Performance Hollow Micro Glass Beads

High performance hollow micro glass beads are a kind of new-type light material which features hollow ball-shaped powder, it will be the main stream of new compound material used in the 21st century. Its true density is about 0.20-0.60g/cm3, diameter about 2-150 micrometers, bulky, low heat conductivity, high compressive strength, low oil absorption and well auto flowability. It is a kind of high quality filling material for products such as heat insulation coating, thermoplastics, fiber reinforced plastics, SMC and artificial stone. It is also a kind of high quality sensitizer for emulsion explosive and is able to increase the storage time, improve the sensitivity and stability of emulsion explosive. For the oil and gas fields, it is widely used to make low density well-cement and low density drilling fluid by fully taking advantage of its low density and high compressive strength.

High performance hollow micro glass beads are a kind of new-type light material which features hollow ball-shaped powder, it will be the main stream of new compound material used in the 21st century. Its true density is about 0.20-0.60g/cm3, diameter about 2-150 micrometers, bulky, low heat conductivity, high compressive strength, low oil absorption and well auto flowability. It is a kind of high quality filling material for products such as heat insulation coating, thermoplastics, fiber reinforced plastics, SMC and artificial stone. It is also a kind of high quality sensitizer for emulsion explosive and is able to increase the storage time, improve the sensitivity and stability of emulsion explosive. For the oil and gas fields, it is widely used to make low density well-cement and low density drilling fluid by fully taking advantage of its low density and high compressive strength.

Features:

Viscosity reducing and mobility increasing

The hollow micro glass beads are small balls, they are of large spherical ratio and ball bearing effect, which reduces the viscosity and internal stress of resin mixtures. As a result, less dynamic heating is produced from the mixed materials during productive process, which makes injection easier and increases productivity by preventing insufficient lubrication and local thermal decomposition.

Higher filling level

The hollow micro glass beads are characterized of minimal surface area and low oil absorption, which enables the mixtures better dispersibility, easy compression and mixing, it can reduce the use of resin considerably, and lower the cost and VOC index by increasing the volume of the hollow micro glass beads.

Contraction and bending lowering

The features of the same nature and high filling level of hollow micro glass beads make the products very stable in size, contraction and bending. Given a proper proportion of filling, the products are greatly improved with their strength, impact resistance and surface hardness.

More economical volumecost

The density of hollow micro glass beads is only a fraction of that of resin. A small volume of the beads can replace heavier materials. When the volumecost but not the cost of weight is taken into account, the high performance hollow micro glass beads can greatly reduce the cost.

Viscosity reducing and mobility increasing

The hollow micro glass beads are small balls, they are of large spherical ratio and ball bearing effect, which reduces the viscosity and internal stress of resin mixtures. As a result, less dynamic heating is produced from the mixed materials during productive process, which makes injection easier and increases productivity by preventing insufficient lubrication and local thermal decomposition.

Higher filling level

The hollow micro glass beads are characterized of minimal surface area and low oil absorption, which enables the mixtures better dispersibility, easy compression and mixing, it can reduce the use of resin considerably, and lower the cost and VOC index by increasing the volume of the hollow micro glass beads.

Contraction and bending lowering

The features of the same nature and high filling level of hollow micro glass beads make the products very stable in size, contraction and bending. Given a proper proportion of filling, the products are greatly improved with their strength, impact resistance and surface hardness.

More economical volumecost

The density of hollow micro glass beads is only a fraction of that of resin. A small volume of the beads can replace heavier materials. When the volumecost but not the cost of weight is taken into account, the high performance hollow micro glass beads can greatly reduce the cost.

甘公网安备 62040202000177号

甘公网安备 62040202000177号